RKR Graphite Private Limited is known for its high tech infrastructure. We use the latest technologies in our sprawling shop floor that uses the best CNC machines. We have access to the latest technological developments in the industry that we read up on to keep up-to-date in the field. Our technology and team work well together so that we deliver high quality and reliable solutions.Our team of trusted professionals is a big asset to us. We have a dedicated research team that studies client requirements and designs the most suitable solutions for them. We also have the most highly trained engineers and technocrats who work hard and meet their goals on time. Our quality assurance team helps us ship zero-defect products to the customer every time. We also conduct regular training sessions for our workforce. All this enables us to give the best customer satisfaction in the industry.

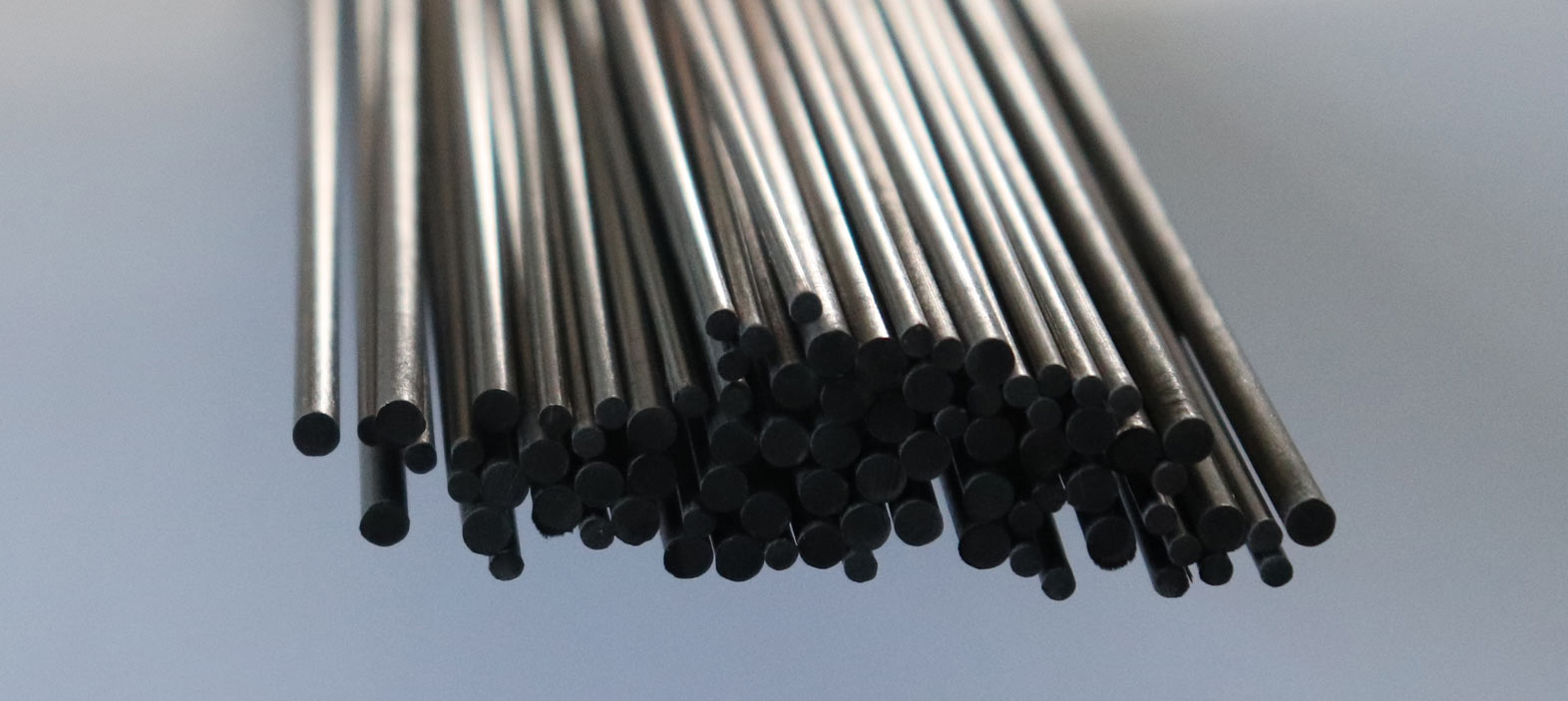

RKR Graphite Pvt Ltd employs a sophisticated manufacturing process to produce high-quality graphite products, integrating advanced technology with precise engineering. The process begins with the selection of high-purity raw materials, which are then subjected to rigorous purification to eliminate impurities. These materials are mixed with binders and processed into the desired shapes through extrusion or molding.

Following shaping, the graphite undergoes a series of high-temperature heat treatments, known as graphitization, to enhance its crystalline structure and optimize its performance characteristics. The final products, including electrodes, crucibles, and powders, are subjected to stringent quality control tests to ensure they meet industry standards. This meticulous process ensures that RKR Graphite Pvt Ltd delivers reliable and high-performance graphite solutions for various industrial applications.

We take extra care with packaging because these high quality products should be in the very peak working condition before they reach the client. To this end, we invest in the latest machines to help with the packaging process. Our electrodes with nipples are carefully packed in wooden crates or sturdy plywood boxes fitted with steel strips to make sure that these delicate items do not move. We also provide extra cardboard padding and ensure a damage-free transportation and delivery to our customer.

RKR Graphite Pvt Ltd ensures that its graphite products are packaged with precision to maintain quality and integrity during transportation. Products are typically packed in durable, protective containers to prevent contamination and damage. The packaging is designed to accommodate various sizes and shapes of graphite items, ensuring secure handling. Each package is labeled with detailed information for traceability and safe handling. This meticulous packaging process helps deliver graphite products in optimal condition to clients worldwide.

RKR Graphite Pvt Ltd offers a diverse range of solutions tailored to meet the needs of various industries. Their product lineup includes high-performance graphite electrodes for electric arc furnaces, precision graphite crucibles for metal melting, and custom graphite components for high-tech applications.

Additionally, RKR Graphite provides advanced materials such as graphite powders and composites, optimized for use in batteries, lubricants, and thermal management systems. By leveraging their expertise and cutting-edge technology, RKR Graphite delivers reliable and innovative solutions that enhance efficiency and performance across sectors like metallurgy, electronics, and energy.